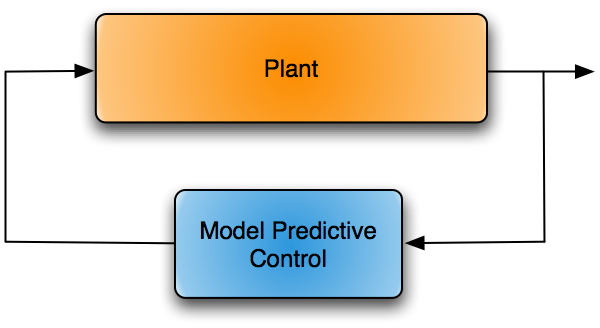

A programmer logic controller is

industrial computer control systems that monitor the state of the input

devices. They make decisions based on the custom program to control the state

of the input devices. These model

predictive controllers are good for any production line or the process as

they may be greatly enhanced using this type of the control system.

Key Benefits

The main advantage of using a PLC is

that they are capable of changing and replicating the operation and the process

while collecting the and communicating the vital information. They are also

modular which means that they can be mixed and matched with many kinds of input

and output devices.

Advent Of PLCs

The first programmable logic

controllers were designed by Modicon. They eliminated the need for rewiring and

adding additional hardware for the configuration of the logic. They increased

the functionality of controls while reducing the cabinet space that housed the

logic.

Anatomy Of A PLC

They have a PLC which contains an

internal program that tells the PLC how to execute the control instructions

that are contained in the user’s program. These programs are stored in the

non-volatile memory which means that they can be accessed even when there is no

power. They are capable of communicating with other devices that include I/O

devices, programming devices, networks and other PLCs as well. They are capable

of communicating and internal diagnostics as well.

Working Of A PLC

Their working is a simple they have

an input scan, program scan, output scan and the housekeeping. The input scan

detects the state of all input devices that are connected to PLC. In the

program scan, all the user created program logic is executed. In the output scan, all the devices that are

connected to the PLC are energized or de-energized. In this step communication

with programming terminals and internal diagnostics takes place.

Programmable Automation Controller

They are easy to configure PLC style

devices, and they come with advanced capabilities that are built into their

design. They are capable of performing complex functions such as controlling

the loop, latching and data acquisition and the delivery. As open architecture

is used in their manufacturing so they can be connected to almost any devices.

Key Characteristics Of PAC

They operate using a single platform,

and a single PAC can do all types of controls, monitoring, data acquisition,

and system expansions. They employ a single development platform. It integrates

closely with the controller hardware and the software and can be programmed

easily with the help of the software tools.

Main Benefits Of PAC

It comes with a single controller and

integrated software that handles multiple functions across many domains. With

the help of the modular designs, the expansions are easier.

Wrapping Up

With the help of a PAC, you can meet

complex requirements, and it also doesn’t need additional components like PLC.

So if you are looking for model predictive controller, your search ends here.